Explosion Proof Lighting Philippines

Explosion-proof LED lighting in the Philippines has emerged as a critical solution for environments where the risk of explosion poses significant challenges. These specialized lighting fixtures are designed to enhance safety in areas where flammable gases, vapors, or combustible dust are present. If you are looking for Explosion Proof Lighting, Corrosion Proof LED Lights and Explosion Proof Lighting Fixtures in Manila Philippines then check out our wide range of Explosion Proof Lighting online.

Explosion Proof LED Philippines

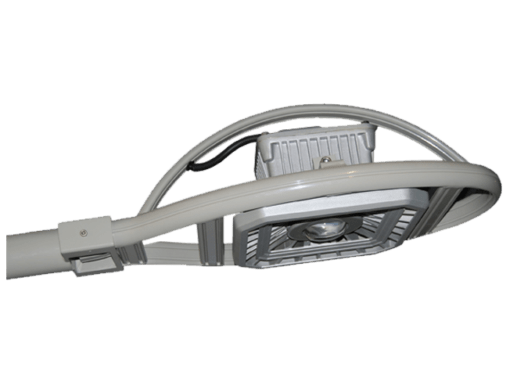

Explosion Proof LED Lighting represents a cutting-edge and indispensable solution for industries operating in hazardous environments. With a focus on safety, energy efficiency, longevity, and compliance, these fixtures provide a reliable and technologically advanced lighting solution for critical applications. You can choose from our wide range led lighting products such as Explosion Proof LED Flood Light, Explosion Proof LED High Bay Lighting, Explosion Proof LED Tube Lighting, and Explosion Proof LED Street Light.

Explosion Proof LED Lighting Philippines

Explosion Proof LED Lighting Philippines – We offer wide range of explosion proof luminaires specifically designed for hazardous area and high risk areas where potentially explosive gases may exist. Our Explosion Proof Lighting solutions are manufactured to strict standards of performance and quality for global market. The result is a range of innovative lighting solutions that combine quality and durability with excellent photometric output.

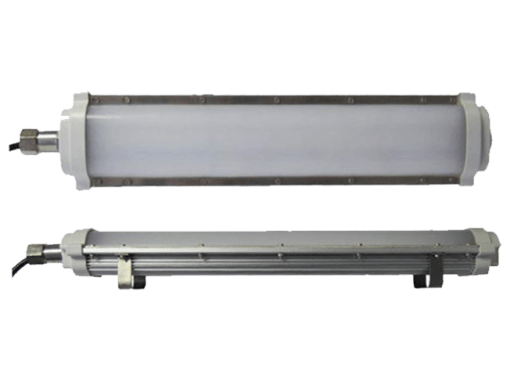

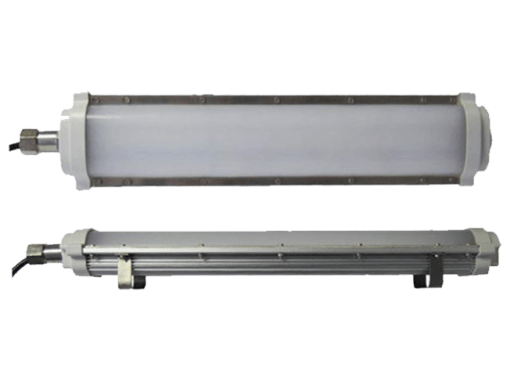

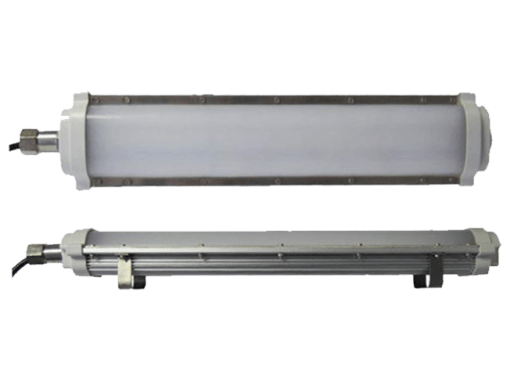

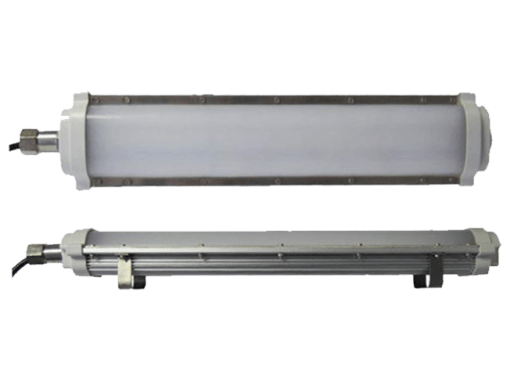

Corrosion Resistant Lighting Fixtures

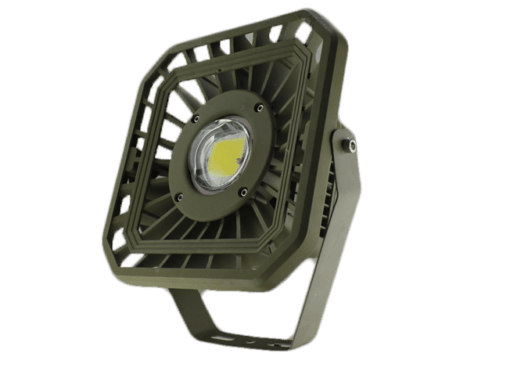

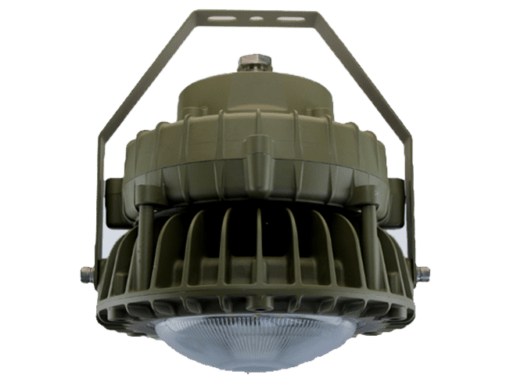

Corrosion Resistant Lighting Fixtures are manufactured from die cast aluminium. The latest LED technology and compact design makes this Explosion Proof LED Light an excellent replacement option for high maintenance cost and outdated high pressure sodium and metal halide lights. Explosion Proof LED Light was designed specifically to replace conventional lighting in a wide variety of Hazardous Area Applications, both indoor and outdoor in the Philippines.

Its high luminous Flux, instant illumination, light weight design and versatile mounting options make it ideal for the Oil Field, Chemical Industry, Steel Industry, Power Plants, Ports, Petroleum Lighting Applications for ATEX and IECEx certificates: Group IIA, IIB, IIC; Zone 1, Zone2; Zone 21, Zone 22; Temperature class: T1 to T6 field Hazardous Area Zones.

Our Explosion Proof Lighting Fixture uses US Bridgelux LED light source and can save 60% on energy than metal halide lamp. The blade-shape housing and heat sink on back cover ensure the explosion proof lamp to efficiently dissipate heat so that prolong LED life. This Explosion proof led lighting also using Taiwan Meanwell LED driver for more stable performance. Adjustable position-locking device on the bracket can tightly fix the lamp to any desired angle, keep the lamp from moving in harsh vibration area.

The anti corrosion aluminum alloy body is powder coated, anti corrosion, dust proof, water proof. Suitable to be used in harsh environment. Flame proof type of protection, safe for use in all kinds of inflammable and explosive area. Explosion Proof Lighting Fixture has a huge variety of lighting applications such as Oil, Gas, Petrochemical, Street Lighting for Hazardous Area Lighting, LED Flood Light for Perimeter Lighting, Marine Lighting and Heavy Industrial Markets. Furthermore, It’s anti corrosion property suitable for harsh environments, including offshore wind farms.

Explosion Proof LED Lighting Technical Specifications:

Power Consumption: 50W | 60W | 80W | 100W | 120W

LED Chip: US BridgeLux

Life Span: 50,000 hrs

Lumens: 120lm/w

LED Driver: Taiwan Mean Well

Input Voltage: 90-305VAC / 127-431VDC

Output Voltage:36VDC

Frequency: 50Hz / 60Hz

Light Color: Warm White/Cool White/Daylight

CCT: 3000K/4000K/6500K

IP Grade: IP66 Outdoor

Anti Corrosion Grade: WF2

Explosion-proof Grade: Ex dIIB T5

Total Harmonic Current: <15%

Insulation Grade: I

Temperature Class: T6

Power Factor: >0.98

Beam Angle: 90°/60°/120°

Material: Aluminium Alloy

Storage Temperature: -40℃ to +60℃

Weatherproof, Corrosion Resistant, Explosion Proof

Explosion Proof LED Philippines

Explosion-Proof Lighting Specifications:

Power Consumption: 50W | 60W | 80W | 100W | 120W

LED Chip: US BridgeLux

Life Span: 50,000 hrs

Lumens: 120lm/w

LED Driver: Taiwan Mean Well

Input Voltage: 90-305VAC / 127-431VDC

Output Voltage:36VDC

Frequency: 50Hz / 60Hz

Light Color: Warm White/Cool White/Daylight

CCT: 3000K/4000K/6500K

IP Grade: IP66 Outdoor

Anti Corrosion Grade: WF2

Explosion-proof Grade: Ex dIIB T5

Total Harmonic Current: <15%

Insulation Grade: I

Temperature Class: T6

Power Factor: >0.98

Beam Angle: 90°/60°/120°

Material: Aluminium Alloy

Storage Temperature: -40℃ to +60℃

Weatherproof, Corrosion Resistant, Explosion Proof

Industry Standards and Certifications

Compliance with industry standards and certifications is paramount in hazardous environments. Explosion-proof LED lighting fixtures undergo rigorous testing to meet safety regulations, providing assurance that they can operate securely in potentially explosive atmospheres. This commitment to compliance makes these fixtures an essential component for industries such as oil and gas, petrochemical, chemical processing, and mining.

Explosion Proof LED Lighting Applications

Oil and Gas Industry: Explosion-proof LED lighting is extensively used in oil refineries, drilling rigs, and processing plants, where flammable gases and vapors are prevalent.

Chemical Processing: Facilities involved in chemical manufacturing and processing utilize explosion-proof LED lighting to mitigate the risk of ignition in the presence of hazardous substances.

Mining Operations: Mines, where dust and gases can pose explosion hazards, employ these fixtures to provide illumination in underground tunnels and processing areas.

Manufacturing Plants: Industries such as pharmaceuticals, food processing, and automotive manufacturing benefit from explosion-proof LED lighting to enhance safety in areas where combustible materials are present.

Warehousing and Storage: Storage facilities with potentially explosive atmospheres, such as those storing flammable chemicals, rely on explosion-proof LED lighting for safe and efficient illumination.

Our Explosion Proof Lighting solutions are manufactured to strict standards of performance and quality for global market. The result is a range of innovative lighting solutions that combine quality and durability with excellent photometric output. Corrosion Resistant Lighting Fixtures are manufactured from die cast aluminium. The latest LED technology and compact design makes this Explosion Proof LED Light an excellent replacement option for high maintenance cost and outdated high pressure sodium and metal halide lights. Explosion Proof Lighting Fixture has a huge variety of lighting applications such as Oil, Gas, Petrochemical, Street Lighting for Hazardous Area Lighting, LED Flood Light for Perimeter Lighting, Marine Lighting and Heavy Industrial Markets. Furthermore, It’s anti corrosion property suitable for harsh environments, including offshore wind farms.

Our Explosion Proof Lighting Fixture uses US Bridgelux LED light source and can save 60% on energy than metal halide lamp. The blade-shape housing and heat sink on back cover ensure the explosion proof lamp to efficiently dissipate heat so that prolong LED life. This Explosion proof led lighting also using Taiwan Meanwell LED driver for more stable performance. Adjustable position-locking device on the bracket can tightly fix the lamp to any desired angle, keep the lamp from moving in harsh vibration area. The anti corrosion aluminum alloy body is powder coated, anti corrosion, dust proof, water proof. Suitable to be used in harsh environment. Flame proof type of protection, safe for use in all kinds of inflammable and explosive area. Explosion-proof LED lighting is an indispensable solution for industries operating in hazardous environments. Its advanced features, coupled with the benefits of LED technology, contribute to safer and more efficient operations while ensuring compliance with stringent safety standards.

LOOK NO FURTHER

EXPLOSION PROOF LIGHTING